Employees: Our Greatest Asset

Quantum Design considers our employees one of our greatest assets. With engineers, machine builders, panel wirers, machinists and support staff from a wide variety of backgrounds we can provide our customers in a large range of industries the best products and services.

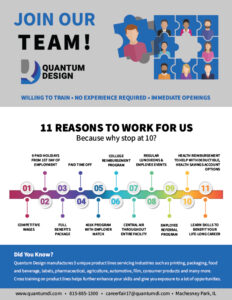

Quantum Design is willing to train and invest in hard-working individuals with a willingness to learn and grow with our company. No experience? No worries! Click on our flyer to the right to see why you should work for Quantum and what qualities we are searching for. Take a chance and apply, every resume is reviewed!

We provide excellent benefits including health, dental, life, vision and disability insurances, a 401K program, PTO, competitive wages, paid holidays and much more. Our entire facility, built new in 2019, is fully air-conditioned including throughout the manufacturing portions of the facility. In addition, we often promote from within the company.

Working for Quantum Design can offer you more than just a job, it can provide you a rewarding career. So what are you waiting for? Send your resume now!

Full job descriptions are listed below. To apply, click the “apply now” button below.

Open Positions

Quantum Design is looking for an experienced Electrical Assembler to join our team. The Electrical Assembler is responsible for the assembly, layout, and wiring of control enclosures and panels per drawings. The job is dynamic and requires a person capable of multi-tasking in a fast-paced environment. The ideal candidate is hard-working, easily adapt to change, and maintains a positive attitude through all situations.

Responsibilities

- Study drawings, design specifications, bill of materials, and electrical schematics

- Layout and punch/cut all holes in electrical enclosures as required per the drawings to mount components

- Layout, drill, and tap all holes in subpanels as required per the drawings to mount components

- Mount components on subpanels and wire per electrical schematics

- Install subpanels in enclosures

- Organize ship loose components

- Ensure enclosures and panels are wired completely and properly with good quality before turning the project over to QC

Knowledge and Skill Requirements

- Knowledge of industry standards and practices as they relate to control enclosure/panel assembly, wiring, and safety

- Knowledge of industrial electrical components such as contactors, relays, disconnects, enclosures, VFD’s, PLC’s, etc.

- Ability to read and interpret drawings, design specifications, bills of materials, and electrical schematics

- Ability to operate hand tools, power tools, and other related equipment

- Good time management skills

- Organize and plan projects to meet project deadlines

- Maintain good quality skills

- Good attention to detail

- Ability to lift 75lbs

- Dependable with a positive attitude and willing to learn

Quantum Design is looking for a hard-working candidate to join our team as a Machine Builder. The ideal candidate is dependable, dedicated, and willing to work both independently and as part of a team building equipment in our manufacturing facility.

Responsibilities

- Mechanical sub assembly

- Machine assembly

- Route cables and pneumatic line

- Label and terminate all incoming field wiring

- Wire 3 Phase and single phase motors

- Abide by all safety standards at all times

- Report any safety or maintenance concerns to management immediately

- Keep all work areas clean and organized

- Strive to meet assembly budgeted hours without compromising quality

- Hold self to a high standard of quality, taking pride in your work

- Attend all safety and production trainings

- Be available for overtime during high volume seasons

Knowledge and Skill Requirements

- Mechanically inclined

- Versed with machine electrics/controls:

- AC & DC circuits

- Ability to read electrical and pneumatics schematics

- Proficient in the use of basic hand tools

- Ability to lift up to 60 lbs

- Excellent attention to detail

- Must be well organized

- Must have a Positive Attitude

- Must work well with others in a team environment

- People skills is a MUST

- Able to climb up and down ladders

- Must have basic hand tools (all specialty tools will be supplied)

Responsibilities

- Apply proper and efficient fabrication and machining methods

- Efficient use of Solidworks and AutoCAD to create models, assembly drawings, detail drawings and bills of material

- Follow all procedures and work instructions with in our IMS system related to this job description

- Attend and lead design reviews with customers and/or QDI sales staff to review and clarify the design specifications of a project

- Assist the QDI sales department with quotations to identify material and labor required to complete project tasks

- Identify, investigate and resolve any conflicts with the customers’ published requirements

- Verify that the design complies with any required mechanical standards, building codes, local regulations, OSHA regulations and good design practices

- Perform and save detailed calculations to support the design decisions made

- Meet with the manufacturing department after the drawings have been released but prior to the beginning of the build to review the drawings, bill of materials and any customer specific requirements. Resolve any issues from the build review that require engineering attention

- Monitor the manufacturing process to assure conformity to the customers’ specifications and sales order requirements

- When applicable, participate in pre-shipment testing to verify component and/or system operation

- Provide on-site technical support to complete system integration and verify final customer acceptance

- Mentor and train other employees as necessary

- Oversee projects to insure they are completed on time and within budget

- Overtime and weekend work may be required on a project to project basis

- Travel required on occasion

Knowledge and Skill Requirements

- Ability to follow instructions and work well with others

- Experienced in machine design including linear and rotary motion, material handling, mechanisms and motion control

- Ability to size structure and select appropriate purchased components such as motors, gearboxes, belts, cylinders, screw drives, chains, bearings, bushings, hardware, etc.

- Thorough understanding of manufacturing capabilities of mills, lathes, grinders, laser and plasma torches, etc. in regards to techniques and tolerances necessary for part manufacture

- Can select cost effective materials and heat treating necessary for part manufacture

- Good working understanding of geometric tolerances

- Working knowledge of hydraulic and pneumatic systems

- Familiar with ISO and ANSI standards

Experience in the following programs/processes is required

- Solidworks

- AutoCAD

- Microsoft Office including Word, Excel and Outlook

- Adobe Reader and/or Acrobat

- Experience in the following programs/processes is not required, but a plus

- Epicor Accounting Software

- Microsoft SharePoint

- Microsoft OneNote

- Microsoft PowerPoint

Exciting opportunities await! We’re looking for a dynamic Control Systems Engineer to spearhead the design of advanced electrical and pneumatic systems. In this role, you’ll blend creativity with technical expertise to develop high-performance control panels and systems, driving innovation and efficiency across projects.

Responsibilities

- Attending design reviews with customers and/or QDI sales staff to review and clarify the design specifications of a project

- Assist the QDI sales department with quotations to identify material and labor required to complete project tasks

- Investigate and resolve any conflicts with the customers’ published requirements

- Verify that the design complies with any required electrical standards, building codes and local regulations

- Perform detailed calculations to support the design decisions made

- Identify and create a bill of materials to meet the control design requirements

- Create the complete electrical and/or pneumatic drawings using AutoCAD software to meet the control design requirements. Obtain approvals from the customer when required.

- Release a complete bill of materials to the purchasing department

- Release a complete set of electrical and/or pneumatic drawings to the manufacturing department along with the customer and/or QDI required documentation to support the build

- Meet with the manufacturing department after the drawings have been released but prior to the beginning of the build to review the drawings, bill of materials and any customer specific requirements. Resolve any issues from the build review that require engineering attention.

- Supervise the manufacturing process to assure conformity to the customers’ specifications and sales order requirements

- Use vendor software to create programs for programmable logic controllers, operator interfaces, supervisory systems and other components as required

- When applicable, perform pre-shipment testing to verify component and/or system operation

- Provide on-site technical support to complete system integration and verify final customer acceptance

- Supervise and train other employees as necessary

- Oversee projects to insure they are completed on time and within budget

- Overtime and weekend work may be required on a project to project basis

- Follow all procedures and work instructions with in our IMS system related to this job description

Knowledge and Skill Requirements

- Knowledge of practical application of engineering science and technology. This includes but is not limited to applying principles, techniques, procedures and equipment to the design and production of control systems.

- Knowledge of arithmetic, algebra, geometry and their applications. Apply these to calculations required for a project.

- Knowledge of the structure and content of the English language including the meaning and spelling of words, rules of composition and grammar. Be able to communicate information and ideas both verbally and in written form so others will understand.

- Knowledge of design techniques, tools and principals involved in developing schematics and implementing software

- Be able to listen and read to interpret customer requirements for a project

- Have good troubleshooting skills for both hardware and software

- Good time management skills

- Organize, plan and prioritize work load to meet project objectives

- Use logic and sound reasoning to evaluate strengths and weaknesses of alternative solutions, conclusions and approaches to problems

- Good judgment and decision making skills to consider the relative costs and benefits of potential actions to choose the most appropriate one

- Be able to determine how a system should work and how changes in conditions, operations and the environment will affect outcomes

- Keep up to date on available products and processes used in control systems

- Junior position is someone coming in with less than five years of experience

- Intern position is someone currently working towards an engineering degree

Experience in the following programs/processes is required

- Microsoft Office including Word, Excel and Outlook

- Adobe Reader and/or Acrobat

- AutoCad

- Rockwell RSlogix 500

- Rockwell RSLogix 5000

- Rockwell FactoryTalk View Studio ME and SE

Experience in the following programs/processes is not required, but a plus

- Epicor Software

- Microsoft OneNote

- Microsoft SharePoint

- Rockwell RSLogix 5

- Siemens Step 7

- Siemens TIA Portal

- Siemens WinCC

- Wonderware

- CNC Control

- Vision Systems

- Servo Motion Control

- VFD Setup and Control

- Ethernet/IP

- DeviceNet

- ControlNet

- AutoCad Electrical

- Bar Code Readers

- NEC, UL, NFPA, CSA and CE codes

Quantum Design is looking for a Territory Sales Manager to join our sales team! The Territory Sales Manager is responsible for achieving sales quotas in the assigned geographical region for the represented product line(s) the are assigned. A great candidate is outgoing, hard-working, willing to travel, and has Sales experience.

Responsibilities

- Cultivating and managing new and existing customer relationships via telephone, email, or face-to-face visits

- Manage all sales activities promptly

- Development of new business opportunities to increase sales revenues

- Stay current on business-related trends, advances, improvements, and changes that could have an impact on the business sales plan

- Assist in the development of an overall sales and marketing strategy for the assigned product line(s)

- Meet assigned targets for profitable sales growth for assigned region

- Establish productive, professional relationships with key personnel in assigned customer accounts

- Non-standard working hours and out-of-town/country travel may be required to effectively cover assigned region

- Attend industry-related technical events and trade shows

Knowledge and Skill Requirements

- 3-5 years of sales/account management experience required

- Bachelor’s Degree in communications, business or related fields preferred

- Demonstrated sales accomplishments in a Manufacturing or Capital Equipment/project environment preferred

- Technical understanding of product line(s) being represented

- Knowledge of the practical application and the implementation of the product line(s), as well as general industry experience

- Be able to estimate projects and coordinate bidding activities in conjunction with engineering, manufacturing and purchasing to ensure accurate scope definition and project pricing

- Be able to negotiate project pricing and long term strategic partnerships with customers and suppliers

- Experience in a business-to-business, large/strategic customer segment

- Proven ability to grow sales through prospecting and new account development

- Strong communication skills both verbally and written

- Must be a self-starter, highly motivated and organized

Experience in the following programs/processes is required

- Microsoft Office including Word, Excel, PowerPoint and Outlook

- Adobe Reader and/or Acrobat

Experience in the following programs/processes is not required, but a plus

- Epicor Software

- Salesforce/ CRM systems

- Microsoft OneNote

- Microsoft SharePoint

Quantum Design is looking for a hard-working candidate who can easily adapt to change to join our Service team. The ideal candidate will be able to work both independently and as part of a team. The primary function of the position is to travel to customer’s sites to set up, start-up, repair, and provide technical support for machinery and equipment. Travel is required regularly.

Responsibilities

- Machine installation, service, and repair – travel required

- Customer training

- Attending to the needs of the customer whenever required

- Phone support – troubleshooting customer calls and assisting with part calls

- Assist the sales department by requesting quotes from the appropriate vendor

- Getting a final acceptance form signed by customer

- Work on the production floor with machine builds while being back in house

- In-house machine testing

Knowledge and Skill Requirements

- Must have a valid driver’s license and car insurance

- Well versed with machine electrics/controls: AC & DC circuits, AC & DC drives, three phase motors, pneumatics, and PLC’s

- Mechanically inclined (previous machine assembly experience a plus)

- Willing to travel regularly; travel is generally weekdays with an occasional

weekend, some international travel may be required - Strong organization skills

- Must have a positive attitude

- Strong people skills

- A professional exterior and attitude

- Excellent customer service skills and demonstrable experience

- Ability to quickly adapt to change and work in a fast-paced environment

- Articulate and good telephone manner

- Keen eye for attention to detail and ability to follow procedures

- Strong sense of initiative and a “can do” attitude

- Ability to work independently and as part of a team

- Positive attitude and willingness to perform tasks outside this description if asked

Education / Experience

• Microsoft Office including Word, Excel, Outlook

• Adobe Reader and/or Acrobat

Employees: Our Greatest Asset

Quantum Design considers our employees one of our greatest assets. With engineers, machine builders, panel wirers, machinists and support staff from a wide variety of backgrounds we can provide our customers in a large range of industries the best products and services.

Quantum Design is willing to train and invest in hard-working individuals with a willingness to learn and grow with our company. No experience? No worries! Click on our flyer to the right to see why you should work for Quantum and what qualities we are searching for. Take a chance and apply, every resume is reviewed!

We provide excellent benefits including health, dental, life, vision and disability insurances, a 401K program, PTO, competitive wages, paid holidays and much more. Our entire facility, built new in 2019, is fully air-conditioned including throughout the manufacturing portions of the facility. In addition, we often promote from within the company.

Working for Quantum Design can offer you more than just a job, it can provide you a rewarding career. So what are you waiting for? Check out our job openings below.

Please use the form to the right to submit a resume or cover letter. If you are interested in a position but do NOT have a resume, please submit your information and we will send you an application.

Open Positions

Quantum Design is looking for an experienced Electrical Assembler to join our team. The Electrical Assembler is responsible for the assembly, layout, and wiring of control enclosures and panels per drawings. The job is dynamic and requires a person capable of multi-tasking in a fast-paced environment. The ideal candidate is hard-working, easily adapt to change, and maintains a positive attitude through all situations.

Responsibilities

- Study drawings, design specifications, bill of materials, and electrical schematics

- Layout and punch/cut all holes in electrical enclosures as required per the drawings to mount components

- Layout, drill, and tap all holes in subpanels as required per the drawings to mount components

- Mount components on subpanels and wire per electrical schematics

- Install subpanels in enclosures

- Organize ship loose components

- Ensure enclosures and panels are wired completely and properly with good quality before turning the project over to QC

Knowledge and Skill Requirements

- Knowledge of industry standards and practices as they relate to control enclosure/panel assembly, wiring, and safety

- Knowledge of industrial electrical components such as contactors, relays, disconnects, enclosures, VFD’s, PLC’s, etc.

- Ability to read and interpret drawings, design specifications, bills of materials, and electrical schematics

- Ability to operate hand tools, power tools, and other related equipment

- Good time management skills

- Organize and plan projects to meet project deadlines

- Maintain good quality skills

- Good attention to detail

- Ability to lift 75lbs

- Dependable with a positive attitude and willing to learn

Quantum Design is looking for a hard-working candidate to join our team as a Machine Builder. The ideal candidate is dependable, dedicated, and willing to work both independently and as part of a team building equipment in our manufacturing facility.

Responsibilities

- Mechanical sub assembly

- Machine assembly

- Route cables and pneumatic line

- Label and terminate all incoming field wiring

- Wire 3 Phase and single phase motors

- Abide by all safety standards at all times

- Report any safety or maintenance concerns to management immediately

- Keep all work areas clean and organized

- Strive to meet assembly budgeted hours without compromising quality

- Hold self to a high standard of quality, taking pride in your work

- Attend all safety and production trainings

- Be available for overtime during high volume seasons

Knowledge and Skill Requirements

- Mechanically inclined

- Versed with machine electrics/controls:

- AC & DC circuits

- Ability to read electrical and pneumatics schematics

- Proficient in the use of basic hand tools

- Ability to lift up to 60 lbs

- Excellent attention to detail

- Must be well organized

- Must have a Positive Attitude

- Must work well with others in a team environment

- People skills is a MUST

- Able to climb up and down ladders

- Must have basic hand tools (all specialty tools will be supplied)

Responsibilities

- Apply proper and efficient fabrication and machining methods

- Efficient use of Solidworks and AutoCAD to create models, assembly drawings, detail drawings and bills of material

- Follow all procedures and work instructions with in our IMS system related to this job description

- Attend and lead design reviews with customers and/or QDI sales staff to review and clarify the design specifications of a project

- Assist the QDI sales department with quotations to identify material and labor required to complete project tasks

- Identify, investigate and resolve any conflicts with the customers’ published requirements

- Verify that the design complies with any required mechanical standards, building codes, local regulations, OSHA regulations and good design practices

- Perform and save detailed calculations to support the design decisions made

- Meet with the manufacturing department after the drawings have been released but prior to the beginning of the build to review the drawings, bill of materials and any customer specific requirements. Resolve any issues from the build review that require engineering attention

- Monitor the manufacturing process to assure conformity to the customers’ specifications and sales order requirements

- When applicable, participate in pre-shipment testing to verify component and/or system operation

- Provide on-site technical support to complete system integration and verify final customer acceptance

- Mentor and train other employees as necessary

- Oversee projects to insure they are completed on time and within budget

- Overtime and weekend work may be required on a project to project basis

- Travel required on occasion

Knowledge and Skill Requirements

- Ability to follow instructions and work well with others

- Experienced in machine design including linear and rotary motion, material handling, mechanisms and motion control

- Ability to size structure and select appropriate purchased components such as motors, gearboxes, belts, cylinders, screw drives, chains, bearings, bushings, hardware, etc.

- Thorough understanding of manufacturing capabilities of mills, lathes, grinders, laser and plasma torches, etc. in regards to techniques and tolerances necessary for part manufacture

- Can select cost effective materials and heat treating necessary for part manufacture

- Good working understanding of geometric tolerances

- Working knowledge of hydraulic and pneumatic systems

- Familiar with ISO and ANSI standards

Experience in the following programs/processes is required

- Solidworks

- AutoCAD

- Microsoft Office including Word, Excel and Outlook

- Adobe Reader and/or Acrobat

- Experience in the following programs/processes is not required, but a plus

- Epicor Accounting Software

- Microsoft SharePoint

- Microsoft OneNote

- Microsoft PowerPoint

Exciting opportunities await! We’re looking for a dynamic Control Systems Engineer to spearhead the design of advanced electrical and pneumatic systems. In this role, you’ll blend creativity with technical expertise to develop high-performance control panels and systems, driving innovation and efficiency across projects.

Responsibilities

- Attending design reviews with customers and/or QDI sales staff to review and clarify the design specifications of a project

- Assist the QDI sales department with quotations to identify material and labor required to complete project tasks

- Investigate and resolve any conflicts with the customers’ published requirements

- Verify that the design complies with any required electrical standards, building codes and local regulations

- Perform detailed calculations to support the design decisions made

- Identify and create a bill of materials to meet the control design requirements

- Create the complete electrical and/or pneumatic drawings using AutoCAD software to meet the control design requirements. Obtain approvals from the customer when required.

- Release a complete bill of materials to the purchasing department

- Release a complete set of electrical and/or pneumatic drawings to the manufacturing department along with the customer and/or QDI required documentation to support the build

- Meet with the manufacturing department after the drawings have been released but prior to the beginning of the build to review the drawings, bill of materials and any customer specific requirements. Resolve any issues from the build review that require engineering attention.

- Supervise the manufacturing process to assure conformity to the customers’ specifications and sales order requirements

- Use vendor software to create programs for programmable logic controllers, operator interfaces, supervisory systems and other components as required

- When applicable, perform pre-shipment testing to verify component and/or system operation

- Provide on-site technical support to complete system integration and verify final customer acceptance

- Supervise and train other employees as necessary

- Oversee projects to insure they are completed on time and within budget

- Overtime and weekend work may be required on a project to project basis

- Follow all procedures and work instructions with in our IMS system related to this job description

Knowledge and Skill Requirements

- Knowledge of practical application of engineering science and technology. This includes but is not limited to applying principles, techniques, procedures and equipment to the design and production of control systems.

- Knowledge of arithmetic, algebra, geometry and their applications. Apply these to calculations required for a project.

- Knowledge of the structure and content of the English language including the meaning and spelling of words, rules of composition and grammar. Be able to communicate information and ideas both verbally and in written form so others will understand.

- Knowledge of design techniques, tools and principals involved in developing schematics and implementing software

- Be able to listen and read to interpret customer requirements for a project

- Have good troubleshooting skills for both hardware and software

- Good time management skills

- Organize, plan and prioritize work load to meet project objectives

- Use logic and sound reasoning to evaluate strengths and weaknesses of alternative solutions, conclusions and approaches to problems

- Good judgment and decision making skills to consider the relative costs and benefits of potential actions to choose the most appropriate one

- Be able to determine how a system should work and how changes in conditions, operations and the environment will affect outcomes

- Keep up to date on available products and processes used in control systems

- Junior position is someone coming in with less than five years of experience

- Intern position is someone currently working towards an engineering degree

Experience in the following programs/processes is required

- Microsoft Office including Word, Excel and Outlook

- Adobe Reader and/or Acrobat

- AutoCad

- Rockwell RSlogix 500

- Rockwell RSLogix 5000

- Rockwell FactoryTalk View Studio ME and SE

Experience in the following programs/processes is not required, but a plus

- Epicor Software

- Microsoft OneNote

- Microsoft SharePoint

- Rockwell RSLogix 5

- Siemens Step 7

- Siemens TIA Portal

- Siemens WinCC

- Wonderware

- CNC Control

- Vision Systems

- Servo Motion Control

- VFD Setup and Control

- Ethernet/IP

- DeviceNet

- ControlNet

- AutoCad Electrical

- Bar Code Readers

- NEC, UL, NFPA, CSA and CE codes

Quantum Design is looking for a Territory Sales Manager to join our sales team! The Territory Sales Manager is responsible for achieving sales quotas in the assigned geographical region for the represented product line(s) the are assigned. A great candidate is outgoing, hard-working, willing to travel, and has Sales experience.

Responsibilities

- Cultivating and managing new and existing customer relationships via telephone, email, or face-to-face visits

- Manage all sales activities promptly

- Development of new business opportunities to increase sales revenues

- Stay current on business-related trends, advances, improvements, and changes that could have an impact on the business sales plan

- Assist in the development of an overall sales and marketing strategy for the assigned product line(s)

- Meet assigned targets for profitable sales growth for assigned region

- Establish productive, professional relationships with key personnel in assigned customer accounts

- Non-standard working hours and out-of-town/country travel may be required to effectively cover assigned region

- Attend industry-related technical events and trade shows

Knowledge and Skill Requirements

- 3-5 years of sales/account management experience required

- Bachelor’s Degree in communications, business or related fields preferred

- Demonstrated sales accomplishments in a Manufacturing or Capital Equipment/project environment preferred

- Technical understanding of product line(s) being represented

- Knowledge of the practical application and the implementation of the product line(s), as well as general industry experience

- Be able to estimate projects and coordinate bidding activities in conjunction with engineering, manufacturing and purchasing to ensure accurate scope definition and project pricing

- Be able to negotiate project pricing and long term strategic partnerships with customers and suppliers

- Experience in a business-to-business, large/strategic customer segment

- Proven ability to grow sales through prospecting and new account development

- Strong communication skills both verbally and written

- Must be a self-starter, highly motivated and organized

Experience in the following programs/processes is required

- Microsoft Office including Word, Excel, PowerPoint and Outlook

- Adobe Reader and/or Acrobat

Experience in the following programs/processes is not required, but a plus

- Epicor Software

- Salesforce/ CRM systems

- Microsoft OneNote

- Microsoft SharePoint

Quantum Design is looking for a hard-working candidate who can easily adapt to change to join our Service team. The ideal candidate will be able to work both independently and as part of a team. The primary function of the position is to travel to customer’s sites to set up, start-up, repair, and provide technical support for machinery and equipment. Travel is required regularly.

Responsibilities

- Machine installation, service, and repair – travel required

- Customer training

- Attending to the needs of the customer whenever required

- Phone support – troubleshooting customer calls and assisting with part calls

- Assist the sales department by requesting quotes from the appropriate vendor

- Getting a final acceptance form signed by customer

- Work on the production floor with machine builds while being back in house

- In-house machine testing

Knowledge and Skill Requirements

- Must have a valid driver’s license and car insurance

- Well versed with machine electrics/controls: AC & DC circuits, AC & DC drives, three phase motors, pneumatics, and PLC’s

- Mechanically inclined (previous machine assembly experience a plus)

- Willing to travel regularly; travel is generally weekdays with an occasional

weekend, some international travel may be required - Strong organization skills

- Must have a positive attitude

- Strong people skills

- A professional exterior and attitude

- Excellent customer service skills and demonstrable experience

- Ability to quickly adapt to change and work in a fast-paced environment

- Articulate and good telephone manner

- Keen eye for attention to detail and ability to follow procedures

- Strong sense of initiative and a “can do” attitude

- Ability to work independently and as part of a team

- Positive attitude and willingness to perform tasks outside this description if asked

Education / Experience

• Microsoft Office including Word, Excel, Outlook

• Adobe Reader and/or Acrobat

What Does Our Team Say About Working Here?